Hypercog progress

admin2023-07-10T09:02:15+02:00The HyperCOG project is developing a cyber-physical system and data analysis tools to be used in process and manufacturing industries. The resulting HyperCOG platform will have the potential to transform processes by improving efficiency and competitiveness using the power of the internet and big data. A cyber-physical system links the physical machinery now used in process industries to digital analysis and monitoring tools that support automated decision making along the whole manufacturing process and optimises production to make factories more efficient.

With HyperCOG now reaching its halfway stage, progress towards meeting its five main objectives is more or less on track despite the project having to operate within the constraints of the most severe COVID-19 restrictions almost since it kicked off at the end of 2019. While these restrictions have delayed some of the work that was planned to take place on site at the three use cases in Spain, Turkey and France, partners working on the technical developments in the lab have made significant progress. Now, as Europe slowly emerges from lockdowns and travel restrictions, most of the development phase is near completion and HyperCOG partners are hopeful that the technology can be prepared for its integration and testing phases.

HyperCOG platform

The main outcome of the project is the development of the HyperCOG platform designed to create more flexible manufacturing, self-adapting environments using cognitive physical systems. The node architecture of this platform, being developed by Lortek, is on target, with the final phase that makes up the HyperCOG architecture being completed with the recent addition of structured messages and a watchdog functionality. Holistic modelling support for detection and assessment of any interruptions to normal processes has also been added, while the whole platform will be operational in line with the cybersecurity framework being developed in parallel. The nodes are currently being tested by MSI.

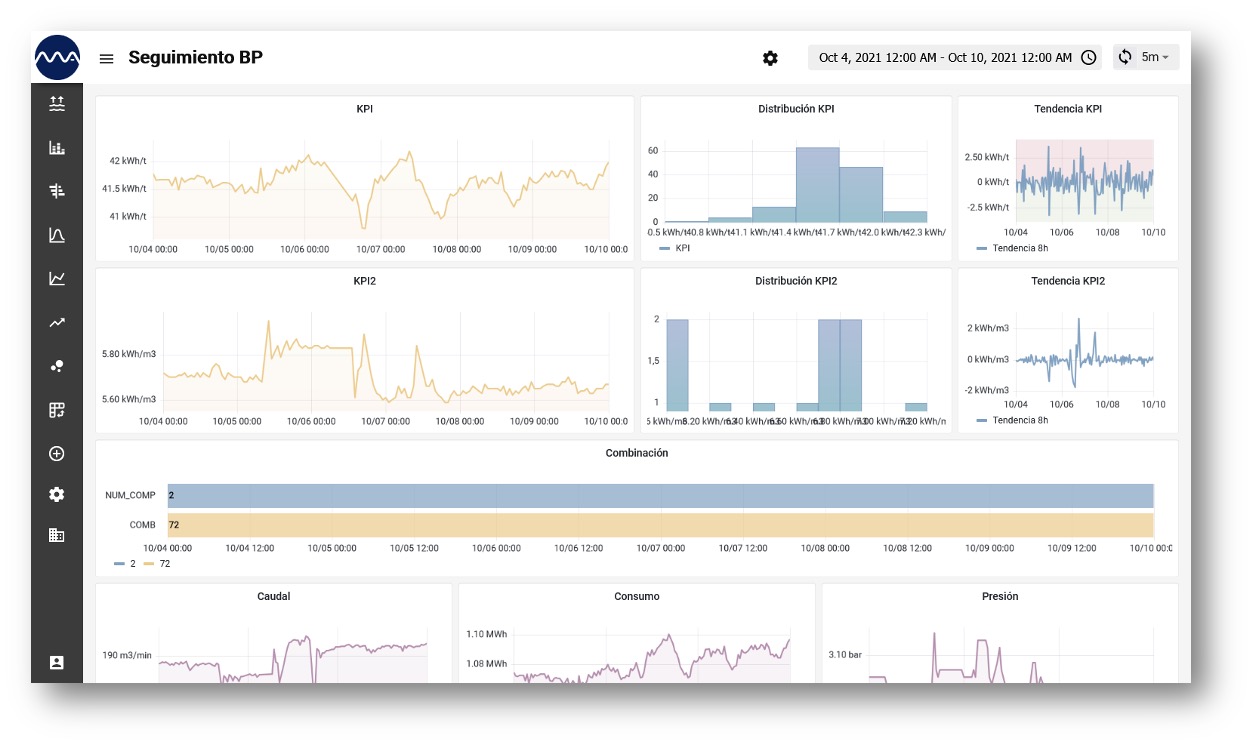

Ongoing work includes the development by MSI of management and monitoring systems in line with the configuration and operation of the HyperCOG architecture. Integration work of the algorithms and sensors, as well as the development of the important human interface for the platform is also ongoing and is in the testing phase, which is being carried out by Lortek and several other partners. On completion of this phase, the integration of the platform on site at the use cases will be started next year.

Advanced data analytics tool

Meanwhile, work at these three plants – steel at Sidenor in Spain, cement at Çimsa in Turkey and chemicals at Solvay in France – is also on target with the development of advanced data analytics tools for extracting knowledge from production databases to optimise operations. This will be the part of the platform that analyses live data from the processing plants to provide real-time information to improve efficiency, cost and even the quality of the final product leaving the factory.

This analysis of this data is at the heart of the HyperCOG platform. At Çimsa, for example, semantic sensor modelling has taken place that is now able to link the cognitive plant level with the core sensor level, while at Solvay, machine learning algorithms have been developed to optimise production. At Sidenor, the optimisation algorithm has been refined in the development of a tool and method for model training and optimisation. Simulation work has also taken place at the use cases to mitigate the fact that visits to the factories by the technical partners has not been possible. Simulations are used in the development of specific data analysis tools for each use case.

Decision support tool

The HyperCOG platform will also provide process industries with a decision-support system designed to use this collected data to enhance decision making at the factory using algorithms to optimise production, reduce waste and save costs. The algorithm developed specifically for the plant at Sidenor in Spain, for example, now works and its ongoing development is focused on making it faster. At present, testing is taking place for this to develop production plans for a whole week, with automated responses to problems that may occur along the line.

At the other use cases, work is focused on sensors and communication and control systems. At Solvay, for example, sensors have been developed to monitor the quality of the chemicals being processed by control systems and regulating processes, while at Çimsa, sensors control the input of raw materials to improve the quality of the output.

In all use cases, data from the various parts of the processes, like image analysis of a cement clinker in cement processing or the intelligent monitoring of ladle temperatures in steel making are collected and analysed to support automated decision making.

Cybersecurity

The HyperCOG platform and these supporting analytical and decision-making tools will only be commercially viable in the real world if they are cybersecure, which is why the project is also focusing on ensuring its cyber-physical systems are secure. All aspects of development to date have, therefore, been developed with security of paramount importance and this fact will become part of the exploitation planning and used as a business enabler.

The key challenge here has been ensuring the security of the connection between bespoke HyperCOG developments and the legacy systems already in place at the factories, which were not designed to be connected in such a way. So, the network and its connection to these systems by HyperCOG has been developed to protect against breaches in security using new secure protocols ensuring cyber-secure systems by design.

Training and reskilling

Other work running in parallel with the technical developments has been that focused on the training and reskilling of the existing workforce involved in the relevant industries. To date this has involved consultation with workers about what they need from the HyperCOG platform and how they will use it most efficiently. This had been fed into the development of the human interface of the decision support tool. While HyperCOG will improve efficiency through digitisation and automation, human input is essential if it is to be viable in the factory setting. Further work in this field will involve the development of training and reskilling modules to enable workers to use HyperCOG efficiently.

Running alongside all this development and integration work has been the Life Cycle Analysis (LCA) that will ultimately produce the evidence that novel industrial cyber-physical systems that are able to increase production performance in process industries.

Life cycle analysis

LCA has been concentrating on the development of baseline scenarios for life cycle sustainability assessment (LCSA) at the three case study plants, while it is also helping to define the overall goal and scope for the project since this will be necessary to interpret the results once the test case scenarios are completed.

Despite complications due to COVID-19 restrictions at the three sites, HyperCOG has been able to progress its LCA by focussing on the situation prior to any intervention at the plants, also called business as usual scenarios.

The first aspect of this task was data collection, where data gathered by sensors has been used to facilitate the integration of the sustainability assessment in the CPS. These LCA databases had to be adapted to the software solution. After that data collection task, an LCA model that eases the dynamic assessment has been developed and a confidential activity report produced using Brightway2, which has some recent developments that facilitate dynamic assessment. This has enabled the inventories to be parameterised to facilitate updating and the work will now continue using this model.